CHAPTER 21 - NANOMATERIAL AND NANOTECHNOLOGY

Effective Date: March, 2007

Last Updated: December, 2014

A. Introduction

The rapidly developing nanoscience and nanotechnology reveal many exciting features of materials at the nanometer (10-9 meter) scale, and the possibility of manipulation of such features to create novel materials or products that are previously unthinkable. Many believe that nanoscience and nanotechnology development will become a new industrial revolution.

On the other hand, together with the numerous beneficial potentials, scientists also warn against possible adverse health and environmental impacts brought by the vastly unknown physicochemical properties of materials at the nanoscale. Among the different environment, health and safety issues, nanomaterials, in particular, nanoparticles probably cause the highest concern because of their potential of rapid uptake by biological system, unknown distribution pathways and potential interactions with various components of the biological system.

B. Nanoparticles

Nanoparticles are previously known in the air pollution field as ultrafine particles, which are defined as particles less than 100 nm in aerodynamic equivalent diameter (AED). Some ultrafine particles are generated by natural processes such as volcanic activities and wild fires. Others are derived incidentally from anthropogenic sources, e.g. engines and incinerators. In general, high energy activities involving organic or inorganic all have the potentials of producing ultrafine particles as one of the byproducts. On the other hand, with the development of nanoscience and nanotechnology, many nanoparticles are purposely made for particular functions. These are usually called engineered nanoparticles, and are defined as engineered particles with at least one dimension smaller than 100 nm.

Nanoparticles have unique physicochemical properties that are not found in their parent materials. In general, they have much higher reactivity, and because of their ultra small size, they can easily penetrate skin or cells, rapidly distribute in human body, and even directly interact with organelles within cells. Their huge surface area to mass ratio increases the chemical activities and therefore allows them to become efficient catalysts. These increased chemical and biological activities result in many engineered nanoparticles being designed for specific purposes, including diagnostic or therapeutic medical uses and environmental remediation that require introduction of these novel materials into human body or the environment.

The novel properties of nanomaterials, however, are a two-sided sword. The same properties that allow the wonderful beneficial uses also imply potentially devastating adverse health effects. Rapid uptake through skin and epithelial cells, capability to translocate along neurons, plus the known toxicity of some parent materials warrant careful environment, health and safety evaluation side by side with every nanomaterial application study.

C. Nanomaterial Toxicity

Researchers worldwide are only beginning to look into toxicity of various nanomaterials. Knowledge of this newly emerged field, sometimes called "Nanotoxicity", is continuously being generated. The following is a discussion of certain known toxicity of several common groups of nanomaterials.

Carbonaceous nanomaterials-Fullerenes, consist of repeating hexagonal and pentagonal rings of carbon atoms. They include buckyballs (C60) and other spherical structures, and single wall and multi-wall carbon nanotubes. Buckyballs are extremely stable. They can trap other atom or molecule inside the carbon structure. Possible applications include superconducting material, drug delivery system, lubricant and catalyst. Carbon nanotubes can also be superconducting, and can be made into mechanically super-strong materials which are 100 times the strength, but one sixth the weight of steel, among many other potential applications.

Carbon has always been considered a non-toxic element, and not very water soluble. However, recent studies found that buckyballs have considerable water solubility, and can cause lipid peroxidation in fish brain after 48 hours at a concentration of 500 parts per billion (ppb). This kind of oxidative stress is usually a first sign of biological damage. Single-wall nanotube has been found to cause other oxidative stresses such as free radical formation and depletion of antioxidants in cells. Metal impurity in synthesis of nanotube may also add to the toxicity. Besides, physical dimensions of some nanotubes may cause pulmonary fibrosis and cancer similar to the effect of asbestos.

Another example of potential toxicity is quantum dots (Q-Dots), which are nanoparticles of semiconducting materials. Their sizes are so small that they interfere with quantum behavior of atoms. One of the results is they display tunable, based on particle size, absorption and emission spectrum over visible wavelength. This property gives quantum dots a strong potential in medical imaging. However, the current quantum dots are made of a cadmium-selenium (CdSe) core with a zinc sulfide (ZnS) shell, and all three metals are known to be toxic to different extents. The high surface area and rapid distribution of the ultra small particles are expected to further escalate the potential toxic effects once introduced into a biological system.

Some nanomaterials have already found their ways into commercial products, such as titanium oxide (TiO2) for photochemical oxidation, self-cleaning paints, sunscreen products, etc.; and zinc oxide (ZnO) in cosmetics and sunscreen products. Other nanoparticles are being used in specialized applications, e.g. iron particles for oxidation of contaminants in groundwater, copper oxide (CuO) for antimicrobial activities; and iron oxide (Fe2O3) as a contrast agent for magnetic resonance imaging. Although most of these parent materials are not considered to be significantly toxic, the ultra small size of the particles again may create unknown toxicity or environmental impacts. There were already studies that showed the toxicity of nanosize TiO2 increases proportionally to the surface area, not the mass as in conventional toxicology. A recent study also measured free nanosize TiO2 particles off the surface applied with a paint containing the nanoparticles.

D. Environmental and Occupational Hazards of Nanomaterials

The environmental, health and safety concerns of nanomaterials in fact span from research safety, manufacturing safety, to consumer (product) safety, and include environmental impacts throughout the life cycle, until final disposal of the nanomaterial products and wastes. Among these concerns, research and pilot scale production safety is most relevant to the research and development work at HKUST.

Due to the rapid development and many uncharted areas in nanoscience and nanotechnology, the practice of occupational health and safety also faces many challenges. As for many conventional workplace contaminants, airborne route is considered the most crucial for worker protection. The shape and size of airborne nanoparticles, and the conglomeration status are some of the main factors determining the hazard. Nanoparticles in liquid phase may present skin hazard when contacted. The hazard of the liquid matrix, its potential interaction with the nanoparticles, e.g. serving as a carrier that facilitates skin penetration, and the conglomeration status of the particles will affect the overall hazard. In either the airborne or liquid phase, the nanomatierals have the potential to adversely impact the environment if they are not properly contained during usage and disposed of afterwards.

E. Challenges in Assessing and Controlling Hazards of Nanomaterials

A major challenge in evaluating hazard posed by airborne nanoparticles is to find a (set of) suitable exposure metric(s). It will be necessary to consider number concentration and surface area, other than the conventional mass concentration, then appropriate sampling and analytical methods, and eventually health-based standards, will have to be developed. Quite a few number concentration direct reading instruments originally designed for ultrafine particle monitoring are available, but their applicability to monitoring of nanoparticles in a work environment remains to be tested. Also the reliability of the detection technology and how "direct" the reading really is are also main concerns to be addressed. In order to differentiate engineered nanoparticles of interest with natural or incidental nanosized particles that may be present in the background, examination by transmission electron microscopy (TEM) remains the golden standard for characterizing and enumerating nanoparticles.

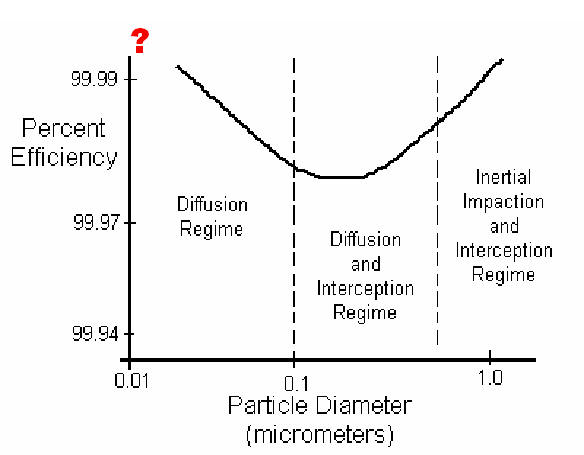

At least one passive sampling method coupled with enumeration by electron microscope has been developed, its precision and accuracy are yet to be determined. Governmental agencies of developed countries such as the National Institute for Occupational Safety and Health (NIOSH) of the US, and Health and Safety Executive (HSE) of the UK, are actively working to fill up these knowledge gaps in assessing hazards of airborne nanoparticles. Another major challenge is control technologies. Traditionally, high efficiency particulate air (HEPA) filters are used for removing airborne particulates. However, before the rise of nanomaterial research, it has never been proved whether HEPA filter can capture nano scale particles. Theoretically the filtering efficiency of HEPA increases with decreasing size below 0.1-0.3 μm, which is the most difficult size range to capture according to physics principles of filtration by fibrous materials. Previously there were only measured data points down to 0.01 μm (10 nm), beyond which the filtration efficiency was by extrapolation. There were also concerns that at low nm range, thermal rebound may become a significant factor that prevent nanoparticles from being captured by fibrous filters.

However, according to preliminary data presented in the Second International Symposium on Nanotechnology and Occupational Health (Minneapolis, October 2005) by a group of researchers from University of Minnesota, 3M and NIOSH, HEPA filter is capable of removing more than 99.97% of particles down to the range of 2-4 nm. No significant thermal rebound was observed. This means with our current knowledge, HEPA filter can be deployed as an effective means to contain and control airborne nanoparticles at least down to the low nm size range.

As for skin protection, most of the glove and protective clothing materials currently in use have not been tested against nanosize particles. Presumably the materials should be protective against nanoparticle conglomerates. Some suggested treating airborne nanoparticles as toxic gas in terms of personnel protection. In any case, until information on interaction of nanoparticles and protective material is available, skin protection should at least be adequate to prevent penetration of the carrier medium of nanoparticles in the liquid phase.

Either in air or liquid phase, nanoparticles tend to agglomerate instead of existing in single particle form. This is helpful from a hazard control point of view. However, certain future applications or manufacturing processes may rely on dispersed nanoparticles. Therefore it is prudent to plan safety measures assuming the worst case scenario.

F. Precautionary Measures and Responsible Nanotechnology

Some basic precautionary measures have been suggested by organizations such as HSE of UK and NIOSH of US. These include treating all nanomaterials that may possess unique physical chemical properties as "new chemicals" for regulatory purpose. Material and safety information raw material can only be viewed, at best, as a starting point or reference for assessing the risk of the nanomaterial product. A good example is carbon, which is practically non-toxic as a parent material; but a group of scientists have already established a toxicity level of oral lethal dose 50 (LD50) of 300 mg/kg for C60 buckyballs, which is considered moderately toxic.

An important concept that worth mentioning is "Responsible Nanotechnology", which basically says, there are many promising applications for nanoscience and nanotechnology, however, there are also uncertainties in potential health and environmental effects. Therefore we should not repeat the errors we made before in cases like DDT and chlorofluorocarbons, where people focused on the beneficial use of the new chemicals so much that they did not carefully check for potential health and environmental impacts until damages were done. Concurrent development of technology and environment, health and safety assessment and controls must go hand in hand in this potentially revolutionary field of research.

The UK Royal Society and Royal Academy of Engineering published a report titled "Nanoscience and nanotechnologies: opportunities and uncertainties" in July 2004. They proposed the following general guidelines, which form a good foundation for responsible nanotechnology development:

-

Treat nanomaterials as if they are hazardous

-

Seek to remove them from waste stream

-

Don't apply free nanomaterials to environment unless benefit clearly outweigh risk

-

Assess potential impact throughout lifecycle of nanomaterial

(The complete report can be accessed at here)

In early 2006, the Government supported the establishment of Nanotechnology and Advanced Material Incorporated (NAMI) under the direction of HKUST to facilitate nanoresearch in Hong Kong and transfer of nanotechnology to local industries. This undoubtedly elevates HKUST to a leading position in nanotechnology development in Hong Kong. It also brings into focus the need to integrate EHS assessment into nanotechnology development all the way from research, pilot production, manufacturing, consumer use and final disposal. This presents a great opportunity for us to realize the idea of "Responsible Nanotechnology", i.e. to not only take advantage of the benefits that nanotechnology brings us, but also ensure that we do not enjoy these benefits in the expense of health, safety or the environment.

G. HKUST Nanosafety Program

Nanomaterial and nanotechnology is a rapidly evolving field, and is one of the focus areas of research at HKUST. The environmental health and safety knowledge about nanomaterials and nanotechnology is also being generated by many researchers worldwide. Even though there are considerable uncertainties, it is prudent to take precautionary measures to minimize the potential of adverse health, safety, and environmental impacts. The following are elements of the Nanosafety Program at HKUST. Due to rapid development of this field, these program elements will be revised when necessary.

1. Facility Review

HSEO has been involved in the planning of laboratory facility for the Institute of Nanomaterials and Nanotechnology (INMT). When faculty members establish other research facilities for nanomaterials and nanotechnology, they should involve HSEO at the planning stage to ensure necessary safety installations are included in the physical facility, safe operational protocols are developed, and suitable personal protective equipment is prescribed and made available to lab workers.

2. Research Proposal Review

A nanosafety section has been added to the research proposal safety review form under the Committee of Research Practices (CRP), where principal investigators are requested to declare whether any nanomaterial will be used, and if so, the physical and chemical properties of the nanomaterial, known toxicity, use conditions, proposed control measures, and final disposal arrangement. Based on the information provided, the Safety Panel of CRP will suggest necessary precautionary measures.

3. Laboratory Visit

At this early stage of development, one of the crucial elements is to establish a database of nanoresearch activities on campus. Based on the information collected from the research proposal review, HSEO staff will visit research groups working on nanoscience and nanotechnology to collect information on the nanomaterials, work processes, potential hazards involved, and waste disposal practices. Since safety standard is yet to be developed, available guidelines such as those from NIOSH and HSE will form the basis of recommendations on EHS issues.

4. Safety Precautions and Safety Installations

As mentioned in Section E above, HEPA filter is a proven method to contain and control airborne nanoparticles. Research should conduct all processes that may give rise to airborne nanoparticles inside one of the following safety devices:

-

Biological safety cabinet (BSC), if a dust-free environment is not critical, a Class 1 BSC can be used. Otherwise, a Class 2 BSC can provide both a dust-free environment and protect lab workers at the same time. However, BSC cannot contain volatile or toxic chemicals, if these are to be used together with nanoparticles. One should use a fume hood equipped with HEPA filtration

-

Fume hood equipped with HEPA filtration

-

Glove box

Be reminded that BSC, fume hood and HEPA filter all need periodic testing to ensure they are properly functioning. Please contact either FMO-LS or HSEO if you have questions about such periodic testing.

5. Safety Precautions and Personal Protective Equipment (PPE)

Laboratory workers handling nanoparticles or other nanomaterials should follow these guidelines:

-

Always ensure personal hygiene and observe good general laboratory practices, including no drinking and eating in the laboratory, always wearing lab coat and safety glasses, etc.

-

Consider the hazards of the parent materials in assessing hazards of nanomaterials. However, remember the nano features of the materials most likely will present many other physicochemical and toxicological properties not found in the parent materials.

-

Never handle nanomaterials with bare hands or expose such materials to bare skin. Until further information is available, use chemical resistant gloves and protective clothing. The material of these PPE items should at least be protective against the carrier medium, such as the solvent, containing the nanomaterials.

-

If it is necessary to handle nanoparticles outside of a safety installations specified in the previous section, use appropriate PPE such as a properly fitted elastomeric respirator with HEPA filter cartridge. Please contact HSEO for requirements of a respirator user. If the exposure risk to nanoparticles is considered low, particulate respirators with a filtration efficiency equivalent to HEPA (e.g. the 100 series approved by NIOSH or P3 by EC standard) may be used.

-

A vacuum cleaner equipped with a HEPA filter may be used to remove nanomaterials from reactors or work areas. However, the integrity of the HEPA filter must be periodically tested to ensure proper functioning.

-

Dispersed airborne nanoparticles, like many other airborne fine particles, can become a fire and explosion hazard. Care must be taken to prevent ignition.

-

Equipment in contact with nanomaterials should be evaluated for residual hazard before servicing, reuse for other purposes, or disposal.

-

Contact HSEO for assistance in evaluating or controlling hazards related to nanomaterials.

6. Waste Disposal

-

Waste containing nanomaterials should be disposed as chemical wastes as a minimum. See Chapter 16 for general chemical waste disposal procedures.

-

Researchers should seek to remove the nanomaterials from the waste stream where possible.

-

Alternatively, researchers should destruct the nano features of the materials where feasible. For examples, acid may be added to waste solution containing quantum dots to dissolve the nanoparticles before disposal.

-

Following the principle of "Responsible Nanotechnology, and the concept of minimizing potential environmental impact, researchers should develop suitable destruction method for nanomaterials as a part of their research.

-

Contact HSEO for assistance in disposal of nanomaterial waste.

7. Exposure Monitoring

Even though standard method has not been established for measuring exposure to nanoparticles yet, some conventional exposure monitoring methods can be employed to provide an estimate of exposure. Some field instruments can also be used to measure airborne nanoparticles. HSEO will continue to monitor the development of exposure measuring technology for nanomaterials.

8. Continuous Improvement

As the field is rapidly evolving, HSEO will continue to monitor the development, especially the environment, health and safety aspects, and will introduce necessary amendments to the nanosafety program. We urge all researchers to integrate EHS considerations into their research projects, and contribute their expertise to the responsible development of nanotechnology at HKUST.

H. Sources of Further Information

The following websites provide updated information concerning EHS of nanotechnology and nanomaterials:

US NIOSH Nanotechnology Topic Page http://www.cdc.gov/niosh/topics/nanotech/default.html

UK HSE - Nanotechnology https://www.hse.gov.uk/nanotechnology/index.htm