Appendix 11C - Dye Lasers

Dye lasers normally use a lasing medium composed of a complex fluorescent organic dye dissolved in an organic solvent. Animal experimentation has shown these dyes to vary greatly in toxicity and potential carcinogenicity; consequently, all dyes should be treated as hazardous chemicals. A few, especially DCM (4-dicyanomethal-2-methy1-6-p-diethylaminostyry1-4-H-pyran), have been found to be very strong mutagens. In many instances, the solvent in which the dye is dissolved plays a major role in the solution’s hazards. Practically all solvents suitable for dye solutions are flammable and toxic by inhalation or skin absorption. Some dye solutions come premixed from the manufacturer, in which case efforts must be made to determine which dye and solvent were used for the preparation. See Table 11C-1 and the Material Safety Data Sheets for additional information. Contact HSEO for additional information.

The following are precautions required during the handling of all laser dyes and solutions. See below for extra precautions to be used for Class M and Class S materials.

|

|

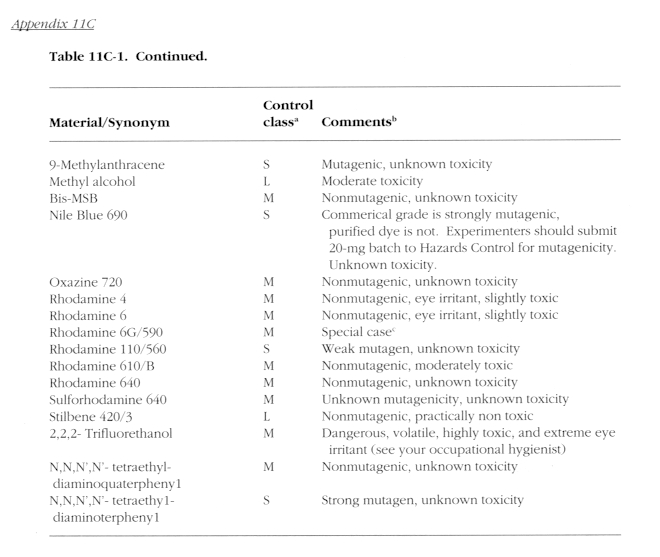

a L = LIMITED control class, M = MODERATE control class, S = STRICT control class. Precautions to be followed for the L class are given above. Extra precautions to be taken when handling the more hazardous classes are given in Appendices A (M class) and B (S class). Dye/solvent mixtures with less than 1% dye shall be handled as appropriate for the solvent, with the exception that for those involving Strict classed dyes, in which the Strict class requirements for container and equipment labelling, as well as spill cleanup, shall be followed. Dye/solvent mixtures with greater than 1% dye shall be handled as appropriate for the component having the strictest control class.

b The approximate mutagen potency of the dye in the standard Ames/Salmonella assay is: “weak mutagen” = <100 revertants/mg; “mutagenic” = 100-1000 revertants/mg; “strong mutagen = 1000- 10,000 revertants/mg; “very strong mutagen” > 10,000 revertants/mg. The Ames test is a reliable predictor of whether a compound is a carcinogen in mammals, but it does not measure the potency of the carcinogen. Thus, a weak Ames mutagen could be a strong carcinogen and a strong Ames mutagen could be a weak carcinogen. Ames test data are used because animal testing is more costly and has not been done on most dyes.

c Follow moderate control class precautions, but also conclude spill cleanup by wiping the area with chlorine bleach (which attacks the amine part of the dye molecule).

Work Practices

Do not eat, drink, smoke, or store food, beverages, or smoking materials in the dye work area.

Post warning signs in conspicuous locations in the dye work area and at approaches to it.

Keep the dye work area clean. Clean up after experiments. Remove as much visible stain as practical during clean up. Janitors shall not do dye clean up work.

Cap off dye lines that are not in use.

Keep containers of solvents and dye solutions closed. Label the containers clearly with the name of the dye and solvent, the concentration of a solution. Also include appropriate warning language such as the word TOXIC , if ethylene glycol is used as the solvent, or the word FLAMMABLE , if an alcohol is used as the solvent. Store the containers in a cool place. Similarly label the dye plumbing systems.

Transport solutions in sealed, labelled containers. Containers need to be made of impact-resistant compatible material. Secondary containment shall be used to transport containers of solvents and dyes and dye solutions

Personal Protective Equipment

Use safety eyewear.

Use any impervious glove when handling dye powders. Consult Table 11C-2 for glove material compatible with various dye solvents.

Fire Safety

Keep heat, flames, and other sources of ignition away from solutions of laser dyes in flammable solvents.

Keep alcoholic waste solutions in flammable-liquid safety cans with the labelling described above .

Keep oxidizing materials away from dyes and solvents.

Use and store flammable liquids in accordance with Chemical Safety Program.

Facilities and Equipment

Install an eyewash and/or shower within 100-ft walking distance or 10-sec walking time of dye/solvent plumbing systems and handling areas.

Pressure test dye laser systems and components if appropriate. Pay special attention to tubing connections.

Install spill pans under pumps and reservoirs or, preferably, enclose them. (Knobs, etc., can pass through holes in the enclosures.)

Spill Cleanup

Clean up small spills (100 ml or less) with absorbant material (such as Kimwipes or kitty litter).

Call FMO-LS and HSEO for assistance when the spilled quantity exceeds 100 ml.

Use gloves and safety eyewear, as specified above, during spill cleanup.

Conclude Rhodamine dye solution spill cleanup with a thorough washing with chlorine bleach.

Call 999 and Security Control Centre (8999) for help if people are injured or have passed out.

Waste Disposal

Dispose of used dye powders or dye solutions absorbed into solids and objects (including personal protective equipment) contaminated with dye in polyethylene plastic (not PVC) bags that are sealed. Immediately place the sealed bags in metal containers or drums that are sealed and labelled. Hazardous waste label can be obtained through FMO-LS. Note: The solvent-soaked materials may be highly flammable.

Dispose of dye solutions in designated containers in the lab. Keep a waste log in which the dyes, solvents, and amounts of each emptied into a container are listed by personnel disposing of the waste. Transfer this information to FMO-LS when the container is full or ready for disposal.

|

Additional Precautions for Dye Work that Warrants Moderate ( M ) Controls

Work Practices

- Minimize the use of DMSO or dioxane solvents.

Personal Protective Equipment

- Use a disposable lab coat or disposable coveralls.

- Gloves made of a material suitable to the solvent and dye.

Fire Safety

- Label containers with the word FLAMMABLE if alcohol, dioxane, or DMSO are used as solvents.

- Keep waste solutions with alcohol, DMSO, or dioxane in flammable-liquid safety cans.

Facilities and Equipment

- Mix dyes in a laboratory fume hood or glove box that provides a designed face/opening velocity of 125 ft/min with a minimum of 75 ft/min. Do not use a hood that blows back inside of a building, even if the exhaust is filtered.

Spill Cleanup

- Use personal protective wear, as specified above, during spill cleanup. Use a disposable dust respirator if exposure to dye dust is possible.

- Call HSEO for assistance if exposure to dye powder is possible.

Additional Precautions for Dye Work that Warrants Strict ( S ) Controls

Work Practices

- Minimize the quantity of pure dye or solutions containing more than 1 percent of dye in storage or in use at any time.

- Limit access to dye work areas. Post signs at the approaches to dye work areas stating: CAUTION - Mutagenic Dye Work Area - Authorized Personnel Only. (Give the name and extension of a responsible person who can act as contact.)

- Advise maintenance and emergency personnel of problems they may encounter in a dye work area before they enter the area.

- Use mechanical pipetting aids when handling dye solutions.

- Use vacuum cleaners approved for toxic dust service or wet methods for housekeeping in the dye work areas.

- Store dye powders or dye solutions containing more than 1 percent of dye in closed containers that are, in turn, kept in closed outer containers. Label both containers to clearly identify the name of the dye and solvent and the concentration of a solution. Also include appropriate warnings such as the words TOXIC - MUTAGENIC, and if an alcohol, dioxane, or DMSO are used as solvents, also include the word FLAMMABLE.

- Minimize the use of DMSO or dioxane solvents.

- Transport dyes and solutions in double containers. Both the inner and outer container need to be sealed and labelled. Put compatible absorbent material in the space between the inner and outer container. The inner container needs to be made of impact-resistant compatible material. (The outer container should also be made of impact-resistant compatible material.)

Personal Protective Equipment

- Use disposable clothing (either disposable coveralls or disposable lab coat).

- Gloves made of appropriate material for the dye and solvent being handled.

Fire Safety

- Keep waste solutions in flammable-liquid safety cans with labelling described above.

Facilities and Equipment

- Use benches and floors with as few cracks, crevices, hard to reach places, and matte-textured surfaces as possible to make cleaning easy. Avoid using dark-colored materials that hide stains. Avoid installing equipment on false floors.

- Provide for separate storage of articles that are contaminated by dyes and those that are not.

- Store pure dyes and solutions containing 1 percent or more of dyes in a designated storage space in the dye work area. Construct the storage space as specified in the preceding paragraph.

- Enclose dye pumps and reservoirs (knobs, etc., can pass through holes in the enclosures).

- Design equipment to minimize leakage.

- Mix dyes in a laboratory fume hood or totally enclosing hood (glove box). The face velocity for a lab hood or the air velocity through any opening of an enclosing hood shall be 100 plus or minus 25 ft/min when used for dye mixing. The hood exhaust must pass through a HEPA filter. Do not use a hood that blows back inside of a building.

Spill Cleanup

- Use a half-face respirator with high-efficiency dust filter cartridges if exposure to dye dust is possible. Prior to use of respirators, persons must receive the lung function test, and respirator training and fit-testing arranged through HSEO.

- Keep people out of the area of a spill and call HSEO for assistance when the spilled quantity exceeds 100 ml or if exposure to dye powder is possible. Report small spills and cleanups to the area Health and Safety Technician.

- A final clean-up check for DCM spills shall be conducted by Ames Assay DMSO Swipes.